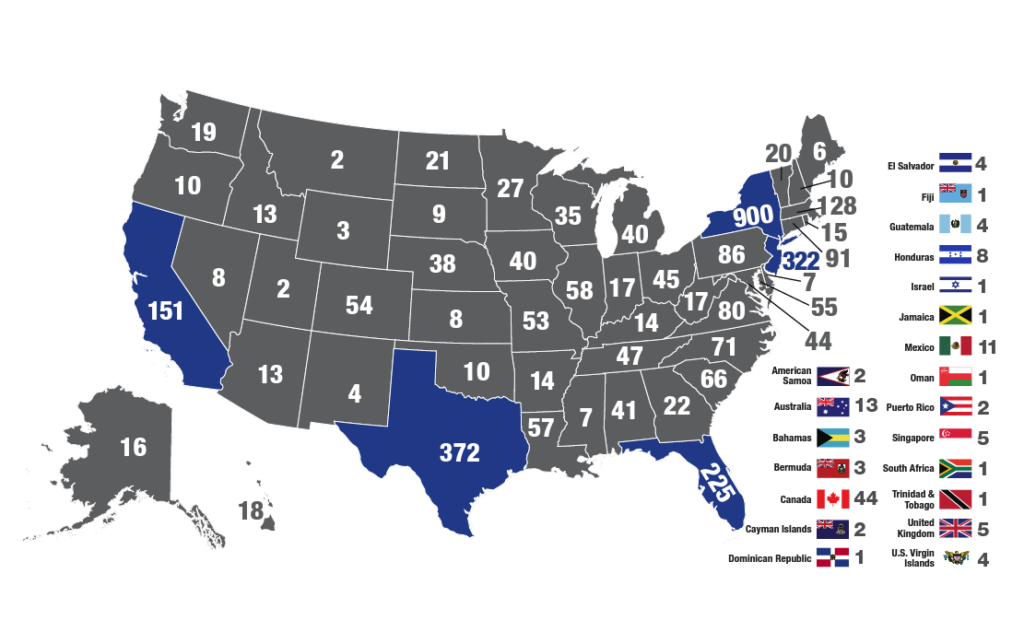

PS Flood Barriers™ has been a part of more than 3,547 projects (protecting more than 43,055 openings), helping companies and organizations do business with confidence.

Capabilities Statement

PS Flood Barriers™ is a division of PS Industries® Incorporated, an industry-leading manufacturer of flood protection products, industrial doors (PS Access Solutions™) and safety/fall protection products (PS Safety Access™) for more than 40 years. With custom fabrication capabilities, we serve a wide variety of industries, including the military, oil and gas, agriculture, food processing, and all types of manufacturing.

The PS Flood Barriers’ foundation is built on innovative design, solid engineering and high-quality manufacturing. In 1997, we learned about the incredible power of water firsthand during the Red River’s disastrous flood in our hometown of Grand Forks, ND. We put those lessons to good use, and today we have a host of flood barrier products to protect facilities, critical infrastructure and assets from devastating flooding.

Core Competencies

Manufacturing

PS Industries is an Original Equipment Manufacturer (OEM) with more than 200,000 square feet of manufacturing space. The company is capable of performing a wide variety of operations in-house, including:

- 6K fiber optic laser cutting

- 4K fiber optic tube laser

- Waterjet cutting

- Industrial metal cutting saw

- CNC punch press

- Precision drilling

- Tube bending

- CNC sheet metal processing

– Shears

– Press brakes

– Folding machine - AWS-certified welders

- Robotic welding

- Industrial liquid paint application

- Powder coating (large capacity – 7.5’x6’x30′)

- Assembly, packaging and shipping

All products are designed and manufactured under one roof in our facility in Grand Forks, North Dakota, USA.

Design/Engineering

State-of-the-art design/engineering resources and in-house design/engineering staff allow products to be created from concept through completion. These resources include:

- Experienced engineers

- Dedicated and experienced design staff

- Finite Element Analysis (FEA)

- 3D CAD modeling

- In-house fixture design and fabrication

- Extensive testing capabilities

- Dedicated team for research and development of new products

Past Performance

- Langley AFB, Newport News, VA

- National Archives, Washington, DC

- Department of Homeland Security, Mobile, AL

- United Nations, New York, NY

- Con Edison, New York, NY

- Port Authority of New York & New Jersey, New York, NY

New York City Housing, New York, NY

Baylor College of Medicine, Houston, TX

Bechtel Headquarters, Houston, TX

Bristol-Myers Squib, Pennington, NJ

- New York School Construction Authority, New York, NY

Differentiators

- Custom-engineered solutions

- Concept through completion

- Industry-proven performance

Connections

- We are registered with SAM.gov

- We are set up with FedBizOpps.gov

- Our CAGE Code is 43360

- Our DUNS number is 078633861

- Our UEI (Unique Entity ID) is Q4V7GF9NUXX5

- NAICS codes

– 332321 Metal Window and Door Manufacturing

– 332312 Fabricated Structural Metal Manufacturing

– 332323 Ornamental and Architectural Metal Work Manufacturing

Certifications

- ISO 9001:2015 Certified Quality Management System

- National Flood Barrier Testing & Certification Program – Platinum Level

- FM/ANSI 2510 Approved on five products

- UL10C NFPA 252 for Fire Rated Flood Doors

- Certified Welders (mild steel, stainless steels, aluminum)